There are many different technical processes taking place at Gainsborough and as the focus of #technicaledit this week, we chose the transformation from Draft to Card.

Draft The design is drawn out, based on a hand-painted artwork, onto draft paper which is the correct ratio of squares to allow for the final fabric picks per inch. The Designer then fills in the drawn design, with painted colour which is coded based on the weft order. Most of our drafts are based on a 400 square width which translates into 400 harness hooks on the jacquard loom. Likewise for every card cut, each card has a capacity of 400 holes – one for each hook of the jacquard harness.

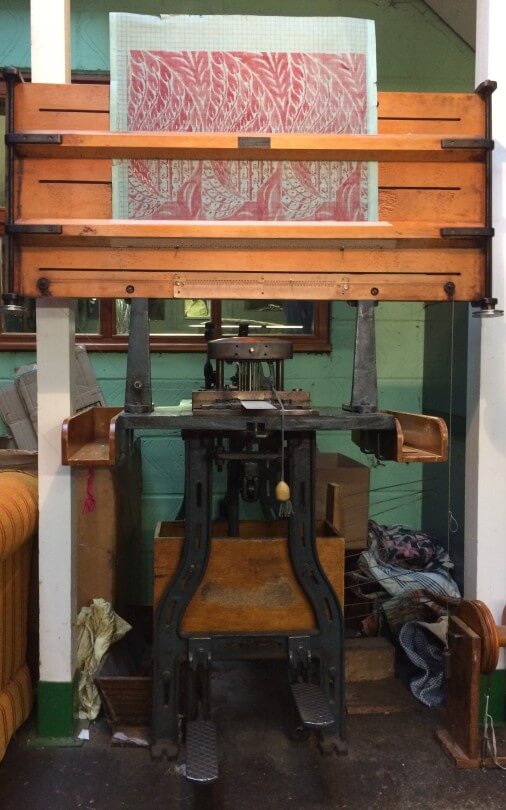

Card Cutting

Each card represents a line of the design repeat with up to 8 holes punched vertically into each card. This works out very well for the card cutter, as each finger controls a hole! If there is more than one draft colour, cutting instructions will be found on the back of each draft and often will require a card to be cut per line, per colour. In this way a relatively small draft can generate a large set of cards if the design is in multiple colours.

Lacing

Once a set of cards has been cut, they must be laced together using the lacing machine. Cord is passed through holes in the cards, specifically cut for this purpose in numerical order, binding them together as a pack. If the card order is incorrect, the final design will not weave as it should once the cards are put up on the loom. We have a set of cards for every design we weave on our 1930s Hattersley Jacquard looms.

Maintenance

The cards we use are literally card and, albeit thick and relatively sturdy, will wear out with age and use, and will have to be replaced. For this purpose we have a repeating machine, which will ‘read’ an existing pack of cards one by one, and copy the information onto a new set of black cards. Although this is still very time consuming, it certainly beats hand-cutting a new set!

This essential, if demanding sequence, is one of the many traditional processes that we keep alive, using the same machinery and the same techniques used here for over a century.