Introducing John Miners:

John has many years’ experience in textiles, and has been involved in the sourcing and supply of historic fabrics for many restoration projects both in the United Kingdom, Europe, and the USA.

With a background at Courtaulds and Pallu and Lake, John developed his historical knowledge thanks to the Victoria and Albert Museum, the late Guy Evans (another historic textile expert who worked with Lyon-based silk mills) and Ian Dale of Angus Weavers in Scotland (who has a workshop in a castle!). His main interest has always been the technical and social history aspects of textiles, rather than simply the styles and designs.

John came to visit us last Monday to go through our Archive (something we have been threatening for a while now), in the hopes that he would be able to educate us. We learnt an awful lot and if you’ve been keeping up with #excavation this week, we have been touching on some of the more technical aspects. Communicating the historical context however, is far trickier to cover in the realms of Twitter and Instagram…

Collection of stacked fabrics in our Archive

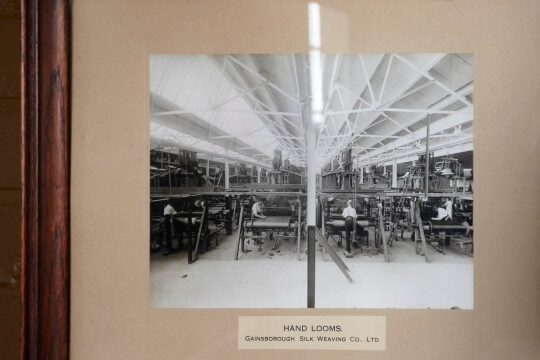

Gainsborough wasn’t founded until 1903 and so was a part of the ‘secondary’ movement in the silk weaving industry at the turn of the 20th Century. As many of the mills in the area went out of business, Reginald Warner grasped the opportunity to set up his own factory with the cheap looms, dyeing equipment and trained labour released by the failing businesses. Gainsborough began as a hand-weaving factory with fly shuttle jacquard looms producing brocade, hand-cut plain and figured silk velvets, Damasks and Brocatelles. Reginald very quickly adopted the power Jacquard loom in the 1920s and had our current factory purpose-built to accommodate the power- and hand-operated Jacquard looms in 1924, though the power looms originally ran on a belt system, powered by a steam engine.

The Hattersley looms and factory as it stands today

A sample from the fabrics Reginald Warner collected from mills closing down across Europe at the turn of the century

Historical Context – How did Sudbury end up as the silk weaving epicentre of the UK?!

If this is a subject that is of interest to you, there is plenty of information out there, but here is our condensed version courtesy of John…

Jacquard weaving only came into existence as we know it today in 1805 and arrived in the UK from the 1820s onwards. The earlier method to create figured woven textiles used the Draw loom, which required a manual operative, often a young boy, instead of the punched cards which control the Jacquard. This principle of storing information on cards was later used in early computers. Figurative silk weaving in the UK is most famously affiliated with the Spitalfields weavers who were mainly Huguenots who had emigrated from France in 1685 to escape the restrictions placed on practising Protestants after the revocation of The Edict of Nantes.

From the late 1780s the Spitalfields master weavers began looking for new locations to outsource work, to avoid paying the minimum wage and set piece rate price enforced by the Spitalfields Act of 1773. Suffolk was ripe for the picking: it was relatively close to London and the wool trade, which had made Suffolk rich from the 14th Century, was in an all-time lull, meaning plenty of idle skilled labour.

Photograph of the Gainsborough factory in the late 1920s

Gainsborough still uses the 1930s Hattersley looms and produces the same designs in the same time-honoured way, although we have disposed of the steam engine! Reginald was a true ‘all-rounder’ and invested in the process from design through to production. Reginald, and the Warners that came after him, custom-built parts of the Jacquard loom to make it more suitable for Gainsborough’s use, enabling large-scale designs like the Medici to be woven on his ‘self-twiller’.

Sudbury is a small market town in Suffolk, and yet there are still three Jacquard silk weaving mills in the area, putting Sudbury on the map as Europe’s largest centre of silk weaving. That said, our approach and our looms are unique, and there is only one Gainsborough!

If you would like to find out more about restoration projects with which John has been involved, a few examples that are well worth a visit include Osborne House, Newton House, Kenilworth Castle, Aspley House, Cliffe Castle, Lotherton Hall, Temple Newsam, Dover Castle, Walmer Castle, Norwich Castle and Melford Hall.

Since January 2013 John has been Chair of Halstead & District Local History Society.